Closed loop-capable stepper motors merge the benefits of stepper and servo motor technology. They run more quietly and have a lower resonance than stepper motors, provide position feedback and control, feature short settling times, and exhibit no step loss at all. They are an alternative to stepper motors if energy efficiency, smooth running and a high load tolerance are required.Compared to servo motors, they have advantages due to their high torque at low speeds, short settling times, correct positioning without back swing and a lower price for sizes that are often smaller.

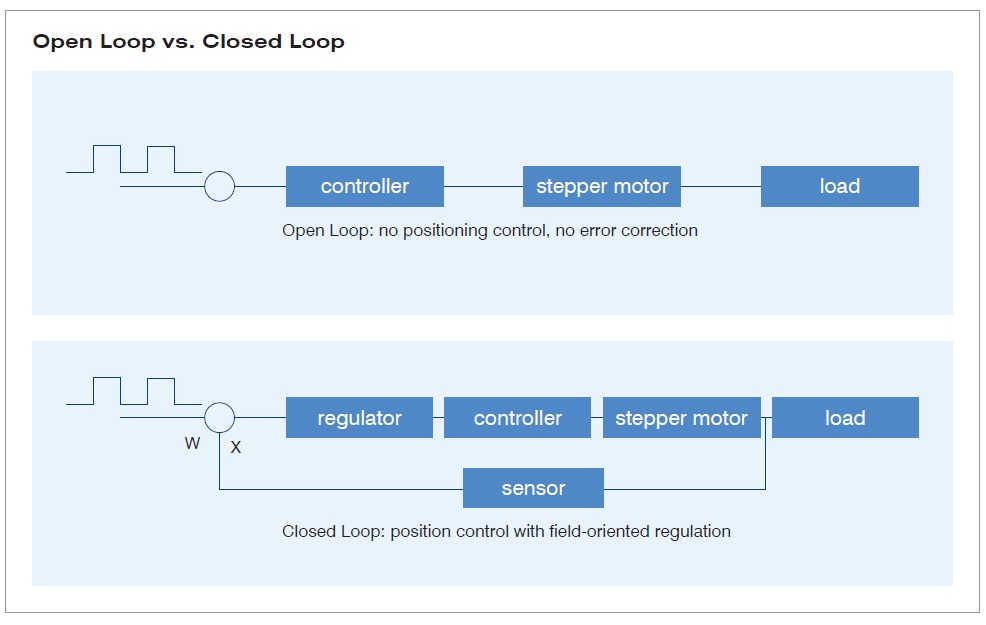

The closed-loop method is also referred to as a sinusoidal commutation via an encoder with a field-oriented control. The heart of closed-loop technology is power-adjusted current control and feedback of control signals. Through the encoder, the rotor position is recorded and sinusoidal phase currents are generated in the motor coils. Vector control of the magnetic field ensures that the magnetic field of the stator is always perpendicular to that of the rotor and that the field strength corresponds precisely to the required torque. The current level thus controlled in the windings provides a uniform motor force and results in an especially smooth-running motor that can be precisely regulated.

True/pseudo closed loop

There are stepping motors that dress themselves up as being closed loops and work with encoders but do not provide any field-oriented control with sinusoidally commutated current control. They only check the step position, and cannot correct step angle errors during operation. True closed loop with field-oriented control compensates step angle errors during a run and corrects load angle errors within a full step.