Why do you use a stepper motor?

Easy to use: 34%

Inexpensive: 17%

Simple operations:16%

No need for tuning: 12%

Other: 21%

Key Points: Ease-of-Use, Simple Operations and Low Cost

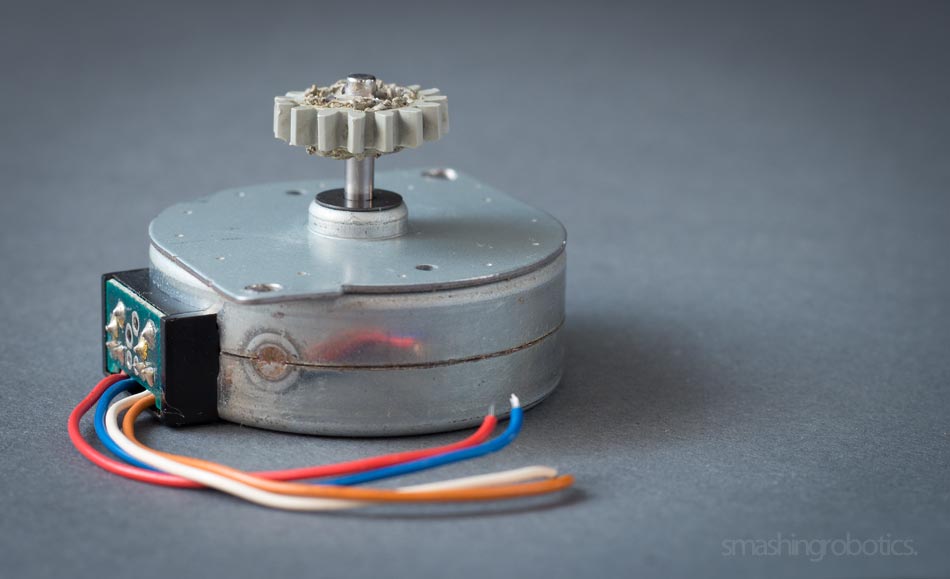

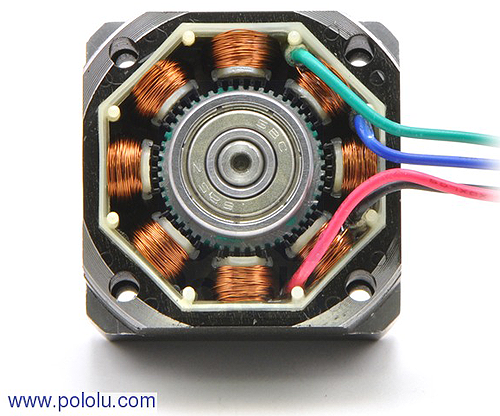

According to the survey of stepper motors users, many favor stepper motors for their “ease-of-use,” “simple operations”, and “low cost stepper motor” derived from the structure and system configuration. It makes sense that many users find such positive aspects in stepper motors, thanks to the simple structure and system configuration. However, some readers may be skeptical about the actual performance of the motor in terms of its accuracy and torque. It is not easy to fully grasp the whole idea unless there are comparison examples against other control motors such as servo motors. By knowing the characteristics and taking on different approaches based on required operations, stepper motors certainly can reduce the cost of the equipment. The characteristics and technical information of stepper motors are explained below:

Impressive “Stopping Accuracy.” Moves Quickly in the “Low / Mid-Speed Range”

Stepper motors have remarkable stopping accuracy, and accurate control with open-loop is possible. For example, when using the RK II Series for positioning of a rotating table, its stopping accuracy is within ±0.05° (with no load). Because stopping position errors do not accumulate between steps, high accuracy positioning is possible. The structure of the stepper motor, which requires no encoder, allows for the simple drive system and low cost.