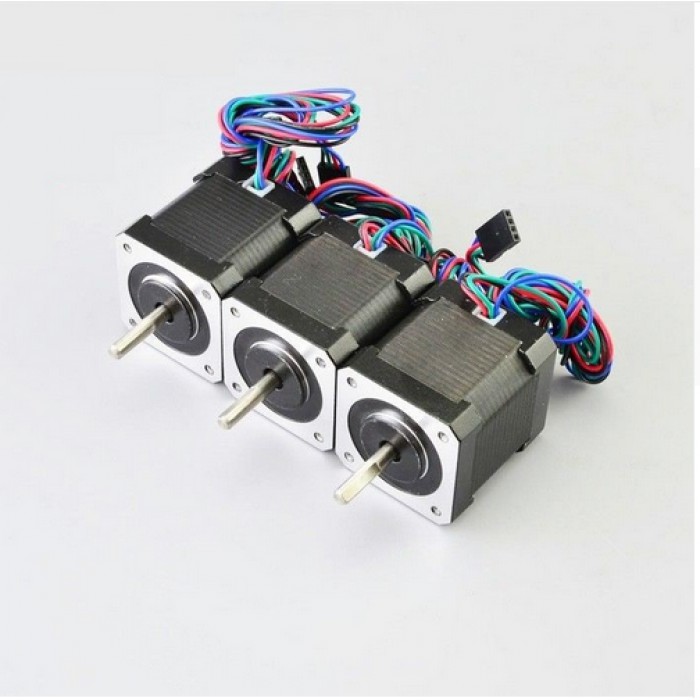

Nema 17 motor is not standard for electrical characteristics of the stepper motor. It is just faceplate and mounting holes standard to make it easier to interchange motors. Most likely you have to check from the specification that what is rated current for that motor and is it unipolar or bipolar one. Choose driver based on that.

Note: Drive can always be more powerful than the motor, but you have to limit your current from the drive side. It’s also possible to use chopper drives with the less current rating, but then your motor runs underpowered.

But one can definitely make assumptions on the motor size that NEMA 17 could use 1A – 2A current and NEMA 23 motor could use around 2A – 5A current.

Final words

This articles scope was to make a high-level overview of how to drive a stepper motor. I hope I delivered and you have now a better understanding of this topic and can start experimenting.

Now the real fun and learning begins.

There is a lot more than these basic concepts I introduced. There will be problems with vibration, torque, cooling motors, choosing hardware, missing steps, calculating steps and configuring software. Stepper motor projects are prone to problems because of all dependencies in the chain. Starting from hardware or power to bad configuration or just wrong program. Basic debugging skills are very handy here and it helps to have extra components to switch in case of hardware malfunction.

Did I answer all basic questions? Or I missed some crucial concept that left you wondering? Let me know about it in the comments. I would be grateful to know so I can improve this article.